How Activated Carbon Transforms Water Purity Across Industries in Saudi Arabia

Clean water is no longer a luxury—it’s a necessity for sustaining life, public health, and industrial performance. But in a world grappling with increasing pollution, climate stress, and industrial demands, ensuring access to pure water is more complex than ever. Activated carbon has emerged as a vital ally in tackling this challenge, offering powerful purification capabilities that are trusted across a wide spectrum of industries.

From industrial discharge treatment to making drinking water safe for human consumption, activated carbon is revolutionizing how we manage water quality. The journey from source to solution involves not just filtration, but a deeper chemical and physical process that captures contaminants invisible to the naked eye. Let’s explore how this material—derived from natural sources—serves as a cornerstone of water purification systems worldwide.

In fact, many industries now rely heavily on advanced activated carbon solutions to meet regulatory requirements, improve water quality, and achieve environmental sustainability targets. The benefits it provides go far beyond simple filtration—it actively transforms water into a safer, more usable resource.

Understanding Activated Carbon: Nature’s Purification Powerhouse

Activated carbon is a form of carbon processed to have an incredibly high surface area and porosity. Its sponge-like structure is what makes it so effective. Tiny pores within the material create a large internal surface area, often exceeding 1,000 square meters per gram, making it perfect for trapping contaminants.

This material is most commonly produced from organic sources such as coconut shells, wood, peat, and coal. Through thermal or chemical activation, it becomes a highly absorbent medium capable of removing impurities through a process called adsorption—a mechanism where molecules stick to the surface of the carbon without being absorbed into it.

Unlike many conventional filters that simply strain particles out, activated carbon works on a molecular level, targeting chlorine, volatile organic compounds (VOCs), pesticides, herbicides, heavy metals, and even taste and odor compounds. Its versatility is what makes it applicable across so many sectors.

The Role of Activated Carbon in Industrial Water Treatment

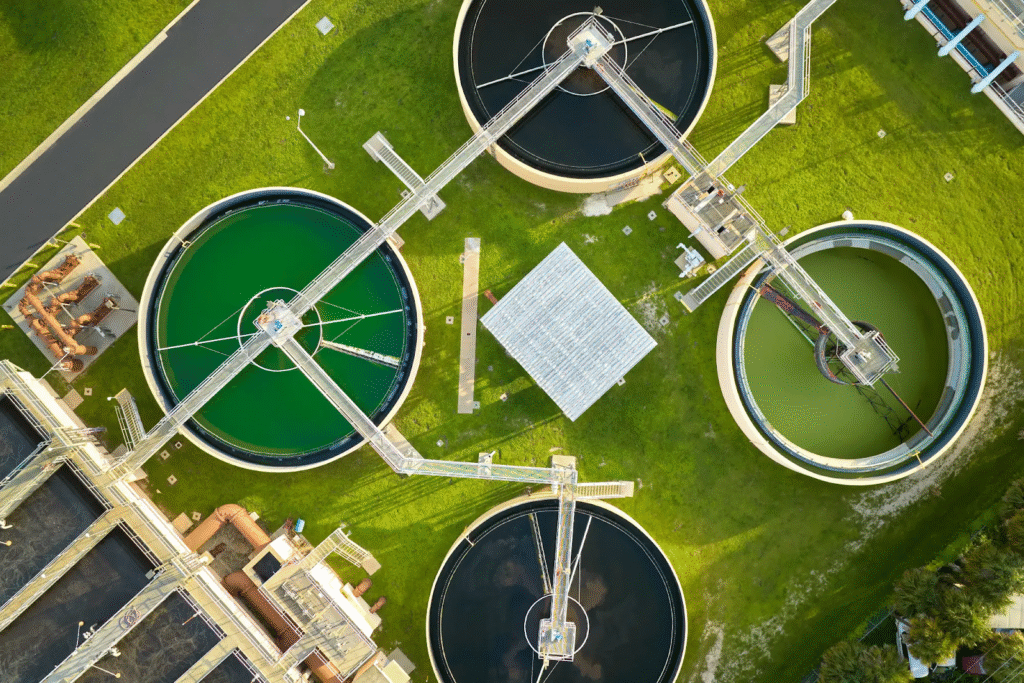

In the industrial sector, water is both a critical input and a potential waste stream. From power plants to chemical manufacturers, factories produce vast amounts of wastewater laden with pollutants. Activated carbon plays a central role in treating this water, helping industries comply with discharge regulations and minimize their environmental impact.

Industrial wastewater often contains organic chemicals, dyes, hydrocarbons, and toxic metals. Activated carbon removes these contaminants with high efficiency, ensuring that treated water can be safely discharged or reused. It’s often integrated into multi-stage treatment systems, working alongside sedimentation, biological treatment, and chemical dosing for optimal performance.

Moreover, in industries such as pharmaceuticals and electronics, where ultrapure water is essential for production, activated carbon pre-treatment ensures that downstream systems like reverse osmosis (RO) and ion exchange operate at peak efficiency by reducing chlorine and organic fouling agents.

Drinking Water Purification: Ensuring Safety at Every Sip

Perhaps the most familiar use of activated carbon is in making drinking water safe and palatable. Whether sourced from groundwater, rivers, or municipal supplies, raw water often contains undesirable compounds that need to be removed before consumption.

Activated carbon excels at removing chlorine, trihalomethanes (THMs), and disinfection byproducts, all of which can cause long-term health effects or give water an unpleasant taste and smell. Additionally, it can adsorb pesticides and pharmaceutical residues that are increasingly found in modern water supplies due to agricultural and urban runoff.

In municipal treatment plants, granular activated carbon (GAC) beds are used in large-scale filtration systems, while powdered activated carbon (PAC) is often added during treatment spikes or emergencies, such as chemical spills.

Even in residential settings, activated carbon is found in faucet-mounted filters, pitcher systems, and under-sink units—proof of its universal trust and effectiveness in ensuring safe water for daily life.

Activated Carbon in Food & Beverage Industries

In food and beverage production, water quality directly affects the safety, flavor, and shelf life of products. Activated carbon is widely used to remove color, odor, and taste contaminants that could otherwise degrade product quality or violate health standards.

For example, in soft drink manufacturing, removing chlorine and organic impurities is essential to prevent off-tastes and to protect sensitive flavoring ingredients. Breweries also rely on activated carbon to ensure that their water profile is suitable for beer styles, while dairy plants use it to maintain hygiene and neutral water for cleaning-in-place (CIP) systems.

The food-grade quality of activated carbon used in these industries is carefully monitored, ensuring no risk of contamination while delivering high levels of purification.

Sustainable Water Management with Activated Carbon

Beyond its immediate filtration capabilities, activated carbon supports long-term sustainability. Water reuse and recycling are becoming increasingly vital in regions facing water scarcity. Activated carbon enables the safe treatment and reuse of water within industrial plants, reducing reliance on freshwater sources and minimizing wastewater discharge.

Furthermore, many activated carbon products are regenerable, meaning they can be cleaned and reused multiple times, reducing material consumption and waste. Advanced regeneration techniques—such as thermal reactivation—make this a cost-effective and environmentally friendly solution over the long term.

Activated carbon also supports circular economy goals by being sourced from renewable materials like coconut shells, which are a byproduct of the food industry.

Challenges and Innovations in Activated Carbon Technology

While activated carbon is remarkably effective, it’s not a silver bullet. Certain contaminants, such as nitrates, fluoride, and some heavy metals, may not be well captured without complementary treatment processes. Additionally, carbon saturation can reduce effectiveness over time, requiring careful monitoring and timely replacement or regeneration.

Fortunately, the industry is advancing rapidly. Innovations in carbon activation techniques, such as microwave-assisted activation and nanostructured carbon composites, are enhancing adsorption capacities and selectivity. Custom-engineered carbons are now available for specific contaminants, while hybrid systems combine carbon with UV, ozone, or membrane filtration for even greater effectiveness.

The Future of Activated Carbon in Water Purification

The global demand for clean water continues to rise, driven by urbanization, industrialization, and environmental pressures. Activated carbon will play an increasingly critical role in addressing this challenge—not just as a filter, but as part of intelligent, integrated water management systems.

AI and IoT-enabled filtration systems are already being tested, using real-time monitoring to predict when carbon filters need replacement and to adjust flow rates for optimal contact time. These smart systems aim to maximize efficiency while reducing operational costs, ensuring clean water with minimal waste.

As industries and municipalities move toward zero-liquid discharge and sustainable development goals (SDGs), activated carbon will remain a key enabler of innovation, compliance, and environmental stewardship.

Conclusion: A Material That Powers Purity Across the Globe

From raw water sources to final treated outputs, activated carbon transforms the water we use and consume—making it cleaner, safer, and more sustainable. Its ability to remove a wide range of contaminants makes it invaluable across industries, from manufacturing to food processing and public health.

As technology continues to evolve and demands for water quality grow more urgent, activated carbon will undoubtedly remain at the forefront of water purification strategies. Its role is not just about filtration—it’s about empowering industries and communities to reclaim and protect one of our most precious resources: clean water.